compressed air bottle testing|hydrostatic gas cylinder testing : distributor CYLINDER HYDROSTATIC TESTING. We perform visual inspection as well as government controlled (TC#047) and certified hydrostatic testing of cylinders of all sizes. We can also refill all SCUBA and SCBA cylinders with laboratory tested, . WEB20 de fev. de 2024 · and most complete Tracking site! Here you can track your Valorant Stats, view your Valorant Ranks, progression, match history, and more! Your Valorant Profile also has all your agents and weapon usage! View our Valorant Database to see all the best weapons, reviewed by players like you.

{plog:ftitle_list}

Resultado da Sharp Point 2016 新程式 • 速度更快更穩定 • 更容易使用的界面 • 支援 iOS 13 或以上 SPTrader Pro HD 是一個真正的原生應用程式,配合全新"觸式交易"模式,令你在智能手機或平板電腦上操作更快更流暢。 SPTrader Pro HD 繼承 SPTrader 的優良傳統,以高速行情和交易取勝,實時帳戶盈虧和即時成交 .

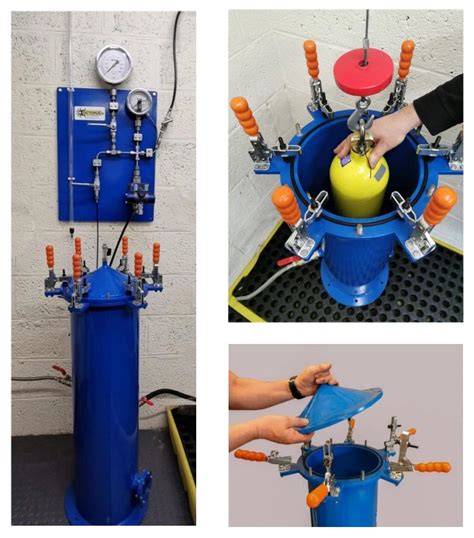

DOT Certified Hydrotesting Service. Department of Transportation (DOT) regulations require compressed air/gas cylinders be periodically tested and inspected internally and externally by a DOT certified testing agency.CYLINDER HYDROSTATIC TESTING. We perform visual inspection as well as government controlled (TC#047) and certified hydrostatic testing of cylinders of all sizes. We can also refill all SCUBA and SCBA cylinders with laboratory tested, .DOT cylinders require re-testing at five year intervals whereas the new UN Cylinders are designed under specification ISO 9809-2; are DOT qualified cylinders and require a 10 year re-test interval. American Airoworks .MES offers hydro-testing and recertification of SCBA and DOT storage cylinders, through multi-point inspections and testing with both auto service and support packages available.

Here are a few compressed air testing options that we have available: Basic Testing. Customers can purchase a simple, disposable detection device for measuring oil aerosol in compressed .Compressed Breathing Air Testing. Trace Analytics has been providing certification to compressed breathing air specifications since 1989. The AirCheck Kit models K201 and . ISO 8573 consists of nine parts or sections that address compressed air. ISO 8573-1 is the primary section that provides contaminants and purity classes. The other eight sections address sampling techniques and . Compressed air testing is a standardized process of determining that the air being used in an industrial process is free of impurities. Typically, compressed air testing procedures .

ISO 8573 – COMPRESSED AIR QUALITY STANDARDS. ISO 8573 IS THE GROUP OF INTERNATIONAL STANDARDS RELATING TO THE QUALITY OF COMPRESSED AIR AND .compressed air using a dryer, with dryer performance being measured as pressure dewpoint. Adsorption or desiccant dryers remove moisture by passing air over a regenerative adsorbent . PARTS 2 – 9 SPECIFY THE METHODS OF TESTING FOR A RANGE OF CONTAMINANTS. ISO 8573.1 : 2001 is the primary document used from the ISO 8573 series as it is this . Employing a Standard for Compressed Air Testing Selecting ISO 8573-1 as the basis for compressed air quality monitoring and testing is the obvious choice, since it provides a common language that all involved parties .This testing determines whether a cylinder is safe for continued use, and is required by the U.S. Department of Transportation for refrigerant cylinders, SCUBA and SCBA tanks, aircraft cylinders, fire extinguishers, beverage (CO2 .

The cylinder may be proof pressure tested. The test is successful if the cylinder, when examined under test pressure, does not display a defect described in § 180.205(j)(1)(ii) or . Upon successful completion of the test and inspection, the cylinder must be marked in .Compressed Air, Ambient Air and Pure Gas Delivery Systems for SQF Practitioners. Looking for Information or Guidance for Required Air and Pure Gas Testing? . TRI Air Testing Inc. 1801 Central Commerce Ct., Bldg. 2 Round Rock, TX 78664. Connect

Whether you need one cylinder or many, our gas cylinders are available in various sizes to meet specific customer needs in a wide range of industrial, medical and specialty gas applications. Get the complete package with compressed gas cylinders from Airgas, an Air Liquide company.Auto service and support packages available! MES specializes in the hydro-testing and recertification of your SCBA and DOT storage cylinders. As the nation’s largest fire equipment distributor and servicing company, MES has 17 in-house service centers staffed with certified technicians trained to meet DOT requirements.We provide international standards and methods for sampling and the testing of compressed air, ambient air and pure gas delivery systems. This includes a multitude of pure gas types up to Five 9’s purity. Additionally, we collect mold & bacteria samples for testing in compressed, ambient, and pure gasses. Date of Manufacture - This date (month-year) indicates the original hydrostatic test. 4. Neck Ring Identification - Displays the name of the current owner of the cylinder. 5. Retest Markings . No compressed gas cylinder should be accepted for use that does not legibly identify its contents by name. If the labeling on a cylinder becomes .

3.1 Cylinder handling Compressed air cylinders are heavy and can be difficult and awkward to move. Improper handling could result in injuries or death. When . EN12245:2009 Standard which specifies the design, testing and production of the cylinder GB Country of approval and mark of the notified body 2006/11 Date of first hydrostatic pressure .TRI Air provides equipment to test compressed air samples as part of air quality compliance, safety, SQF. Medical. Solutions for medical gas testing standards including NFPA 99. Fire Service. Compressed breathing air quality for firefighters and SCBA air, NFPA 1989, CGA Grade D, .Why do compressed air cylinders need to be inspected? It is a legal requirement to have compressed air cylinders that are used for breathing air re-tested every 5 years until the end of their service life. This requirement applies to both steel and composite cylinders. For older composite cylinders, the time limit may even be set at 3 years. Request your maintenance .

This compressed air is very important to start main engine or auxiliary engine. Purpose of Air Bottle. . what are the ways to test an air bottle for leakage ? and why is the end piece tapperd before its welded to the shell ? Terence Marshall says: July 31, 2014 at 11:31 am.When it comes to Compressed Gas & Air Pressure Gauges, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support.2. Cylinder Serial Number 3. Date of Manufacture: • This date (month-year) also indicates the original hydrostatic test. 4. Neck Ring Identification: • The cylinder neck ring displays the name of the original owner of the cylinder. 5. Retest Markings: • The format for a retest marking is: Month – Facility – Year – Plus Rating .

Our compressed air sampling kits — the AirCheck ™ Kits — are designed to capture compressed air and gas samples for purity analysis by our laboratory. We can accommodate Compressed Air & Gas Testing Specifications like ISO 8573, NFPA 1989, NFPA 99, OSHA, CGA, CSA, and many more. Contact Us to discuss your compressed air testing needs.SAS is capable of testing all cylinders approved for use in the UK, including: Diving cylinders; BA cylinders; Paintball cylinders; Storage cylinders; Mixed gas cylinders; Airgun cylinders; Industrial cylinders; Specialist cylinders; We can test any cylinder between 0.1 litre and 256 litre, and can also collect and deliver them to you. In this piece, we will further explore how each type of impurity can occur and will discuss how to test compressed air/gas quality. Compressed Air Testing Methods. Each of the types of potential air quality issues has different underlying causes and testing methods. In general, compressed air testing is governed by ISO 8573.The final technology you can employ is gas chromatography, a process often used in analytical chemistry to test the purity of a particular substance, such as compressed air in this case. This is the only method that can be used to ensure that you are in compliance with even the most stringent air quality requirements.

compression test 1967 v8

Compressed Air. Regular ambient air can also be compressed for a variety of applications where ultra-high purity is not critical. When combined with a fuel gas, compressed air produces a flame with a lower temperature than an oxyfuel flame. An air-fuel flame is suitable for brazing, soldering and carbon coating lower-temperature alloys.3M™ Scott™ offers a complete assortment of compressed breathing air cylinders, including our lightest 5500 psig cylinder, to meet the needs and demands of all SCBA users. Over the years, compressed breathing air cylinders have been providing SCBA users with a supply of fresh air. The original cylinders were made of steel and quite heavy.DOT and ISO cylinders are the heart of many Breathing Air storage systems in fire departments, paintball, SCUBA and industry applications.A system may include two or more UN-ISO DOT cylinders, mounted in your facility, on a mobile air trailer or out of sight inside your fire truck and they are often overlooked for the required Hydrostatic Testing .

Breathing Air Cylinder Hydrostatic Testing. The testing of compressed gas cylinders, including those containing breathing air for SCBA, is regulated by the United States Department of Transportation (DOT) under CFR 49. Breathing air cylinders must be . Pneumatic cylinder parts. Figure 2 shows the main components of a double-acting pneumatic cylinder. Cap-end port (A): The cap on the backend of the pneumatic cylinder where compressed air can enter or exit. Tie rod (B): Tie rods are long rods that hold the pneumatic cylinder together. They run the length of the pneumatic cylinder and connect the .

This stands for the month. The gas bottle test on this cylinder was in January. The second yellow square with 14 stands for the year. And for this cylinder it tells you that this gas cylinder’s last test happened in 2014. This particular compressed gas cylinder bottle was last tested in January 2014.Compressed Air Gas Bottles & Cylinders can be purchased at Gas UK. Supplied from 5 to 20 Litre Cylinders – 0800 133 7490Hydrostatic Facility, at Safe Air Systems, is a state of the art testing facility with 4 computer operated test stands that have the capacity to test cylinders in large quantities. Our Hydrostatic Testing Systems are single pump units that have the capacity to test cylinders simultaneously at a rate of 7 cylinders per testing cycle.

hydrostatic gas cylinder testing

hydrostatic cylinder testing procedure

gas cylinder testing

Pinnacle Bank is located at in Oneill, Nebraska 68763. Pinnacle Bank can be contacted via phone at (888) 763-1370 for pricing, hours and directions.

compressed air bottle testing|hydrostatic gas cylinder testing